Label printers are essential tools in various industries, including manufacturing, retail, and logistics. They play a crucial role in creating and printing labels for products, packages, and shipping containers. In this comprehensive guide, we will explore how label printers work, their types, and the key components that make them function effectively.

Recommended Best Label Printer 2024-2025

| Recommendation | Product |

| Best Overall | Nelko Wireless Shipping Label Printer |

| Popular Choice | PEDOOLO Bluetooth Shipping Label Printer |

| Best Value | iDPRT Bluetooth Thermal Label Printer |

| Best Budget | POLONO P31S Label Maker Machine |

| Another Excellent Pick | JADENS Thermal Shipping Label Printer |

Types of Label Printers

Label printers come in different types, each designed for specific applications. The common types include:

- Direct Thermal Printers

- Thermal Transfer Printers

- Inkjet Label Printers

- Laser Label Printers

Each type of label printer utilizes different printing technologies and is suitable for various printing requirements.

Key Components of a Label Printer

A label printer consists of several key components that work together to produce high-quality labels. These components include:

- Print Head

- Platen Roller

- Ribbon (for thermal transfer printers)

- Label Roll Holder

- Control Panel

- Interface (USB, Ethernet, Wi-Fi)

The print head is a critical component that applies heat to the label paper, resulting in the creation of text and images. The platen roller helps feed the label stock during the printing process, ensuring accurate and consistent printing.

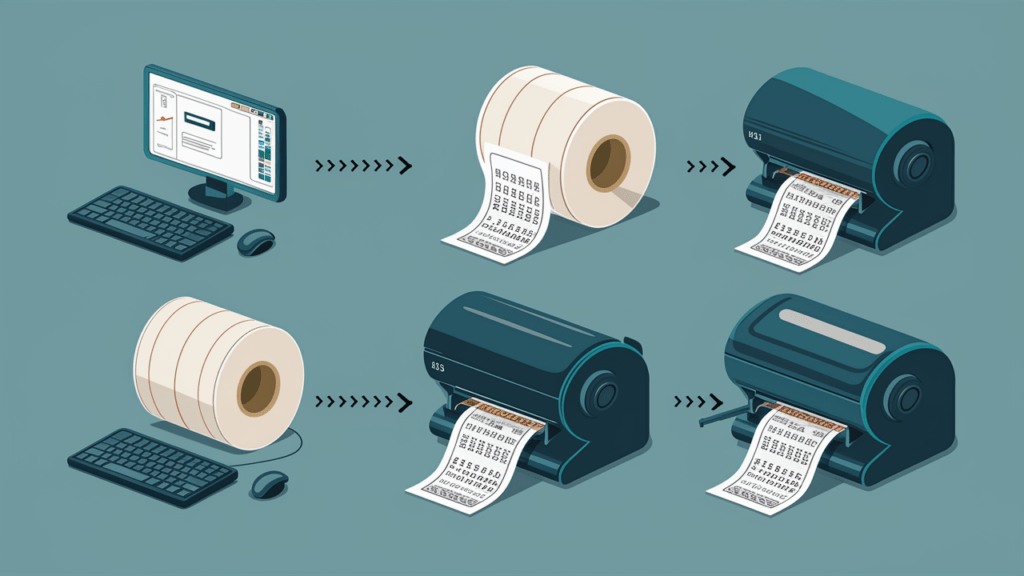

How Label Printers Work

Label printers utilize different printing technologies to produce labels. Let’s explore how some of the common types of label printers work:

Direct Thermal Printers

Direct thermal printers use heat-sensitive paper and do not require ink or toner. The print head applies heat to the paper, causing a chemical reaction that results in the creation of text and images. Direct thermal printing is ideal for producing temporary labels such as shipping labels and receipts.

Thermal Transfer Printers

Thermal transfer printers use a thermal print head to transfer ink from a ribbon onto the label material. The ink is transferred through heat, resulting in durable and long-lasting labels. Thermal transfer printing is suitable for applications that require high-quality, permanent labels such as product labels and barcode labels.

Inkjet Label Printers

Inkjet label printers work by propelling tiny droplets of ink onto the label material to create text and images. This printing technology is known for its high-resolution output, making it suitable for printing colorful and detailed labels for product packaging and promotional materials.

Laser Label Printers

Laser label printers use laser technology to produce high-quality labels. The printing process involves the use of a laser beam to create electrostatic charges on the label material, which attract toner particles to form text and images. Laser label printers are commonly used for printing barcodes, shipping labels, and office labels.

Advantages of Label Printers

Label printers offer several advantages, including:

- High-speed printing

- High-resolution output

- Customization options

- Cost-effective label production

- Durable and long-lasting labels

These advantages make label printers indispensable in various industries, contributing to efficient labeling and identification processes.

What is the Difference between a Thermal Printer And a Label Printer: Unveiled

A thermal printer uses heat to print, while a label printer is specifically for printing labels. Thermal printers are versatile and can print various materials, while label printers are specialized for label printing.

Thermal printers are more suitable for high-volume printing tasks, while label printers are ideal for businesses needing to print labels consistently and efficiently. Both types of printers offer different functionalities and are essential tools for businesses in various industries. Understanding the distinction between a thermal printer and a label printer can help businesses choose the right printing solution to meet their specific needs and requirements.

Introduction To Thermal And Label Printers

Thermal printers use heat to produce an image on paper, whereas label printers are designed specifically for printing labels. The core function of a thermal printer is to print on thermal paper, while a label printer can print on various materials. Common uses of thermal printers include receipts and shipping labels, while label printers are commonly used for creating product labels and barcodes.

Types Of Thermal Printers

Thermal printers use heat to produce images and text on paper. Label printers are a type of thermal printer used specifically for printing labels. There are two types of thermal printers: direct thermal and thermal transfer. Direct thermal printers use heat-sensitive paper that turns black when heat is applied, making them ideal for short-term applications. Thermal transfer printers, on the other hand, use a ribbon to transfer ink onto the label, resulting in more durable and long-lasting prints. They are suitable for applications requiring high-quality and long-lasting labels. Both types have their advantages and disadvantages, so it’s important to choose the one that best fits your specific printing needs.

Label Printers Explained

Label printers are essential for businesses. The main difference between a thermal printer and a label printer lies in their printing methods. Thermal printers use heat to produce images, while label printers create high-quality labels for various purposes.

| Label Printers Explained |

| Role in Barcode Printing |

| Label printers play a crucial role in barcode printing processes. They utilize specific technologies to produce accurate and durable labels. Two main technologies used are direct thermal and thermal transfer printing. Direct thermal labels don’t require ink, as they utilize heat-sensitive paper. On the other hand, thermal transfer printing involves a ribbon that transfers ink onto the label. Both methods are suitable for different applications, depending on requirements for quality and durability. |

Key Features Of Thermal Printers

Thermal printers use heat to produce images, while label printers are specifically designed to print labels. Thermal printers are versatile, printing on various media, whereas label printers are tailored for label printing only. The key difference lies in their intended use and printing capabilities.

| Key Features of Thermal Printers |

| Print Mechanism |

| Thermal printers use heat to transfer ink from a ribbon onto paper, creating images and text. Direct thermal printers use heat to create images and text directly on the paper, while thermal transfer printers use heat to transfer ink from a ribbon onto paper. Thermal printers are known for their fast printing speed and low cost per page. |

| Material Requirements |

| Thermal printers require special thermal paper or ribbon that is heat-sensitive. This can be more expensive than regular paper or ink cartridges used in other types of printers. Thermal printers are also sensitive to heat and may fade in direct sunlight or at high temperatures. Additionally, thermal printers are typically monochromatic and not suitable for color printing. |

Thermal printers and label printers are two different types of printers used for different purposes. Thermal printers use heat to transfer ink onto paper, while label printers are specifically designed to print labels. Thermal printers are known for their fast printing speed and low cost per page. However, they require special thermal paper or ribbon that is heat-sensitive and may fade in direct sunlight or at high temperatures. Label printers, on the other hand, are designed to print high-quality labels and are ideal for printing shipping labels in eCommerce businesses. Overall, the choice between a thermal printer and a label printer depends on the specific needs of the user.

Advantages Of Thermal Printing

Thermal printers use heat to produce images, while label printers are a type of thermal printer specifically for labels. The main difference lies in the application: thermal printers are versatile, while label printers are designed for printing labels efficiently.

| Advantages of Thermal Printing |

| Speed and Efficiency |

| One of the biggest advantages of thermal printing is its speed and efficiency. Thermal printers use heat to produce high-quality images and text on paper or labels, which means they can print quickly and accurately. They are often used in industries where high-speed printing is necessary, such as in retail and logistics. With thermal printing, you can print hundreds of labels or receipts in just a few minutes. |

| Maintenance and Durability |

| Another advantage of thermal printing is its low maintenance and durability. Thermal printers have fewer moving parts and do not require ink or toner, which means they are less likely to break down or require frequent repairs. They are also more durable than other types of printers, making them ideal for use in harsh environments. With proper care and maintenance, a thermal printer can last for many years. |

Limitations Of Thermal Printers

Thermal printers are limited in color options and require special paper due to heat sensitivity, not ideal for color printing. In contrast, label printers offer versatility in printing labels for various applications and industries. Thermal printers utilize heat-sensitive paper or ribbons, while label printers provide quality label printing solutions.

| Limitations of Thermal Printers |

| – Limited Color Capabilities: Thermal printers are typically monochromatic, not suitable for color printing. |

| – Media Sensitivity: Thermal paper is sensitive to heat, which can cause fading in direct sunlight or high temperatures. |

Label Printer Capabilities

Label printers offer versatility in label creation, allowing for customization of labels for various purposes. Whether it’s for product labeling, shipping, or organization, label printers provide the flexibility to design and print labels according to specific requirements.

Furthermore, the longevity of printed labels is a key advantage of label printers. The labels produced are durable and resistant to fading, ensuring that the information remains clear and legible for an extended period.

Choosing Between Thermal And Label Printers

Thermal printers use heat to produce an image on paper, eliminating the need for ink or toner. They are cost-effective due to the lower maintenance and supply costs. On the other hand, label printers are designed specifically for printing labels, making them ideal for applications requiring high-quality, long-lasting labels. They are often more expensive to operate due to the need for special label stock and ribbons. While thermal printers are suitable for general purpose printing, label printers are ideal for applications where durability and high print quality are essential.

Conclusion: Selecting The Right Printer

Business Needs Assessment: Before choosing between a thermal printer and a label printer, consider the specific needs of your business. Evaluate the volume and type of printing tasks to determine the most suitable option.

Future-Proofing Your Choice: Anticipate the future growth and changes in your business. Select a printer that can adapt to evolving printing needs and technologies to ensure a long-term solution.

Frequently Asked Questions

How Does A Label Printer Work?

Label printers use thermal transfer or direct thermal technology to print labels by applying heat to a special thermal paper or ribbon.

What Is A Label Printer Used For?

Label printers are used to create various types of labels, including address labels, shipping labels, barcode labels, and product labels.

What Are The Benefits Of Using A Label Printer?

Label printers offer a range of benefits, including cost savings, convenience, and the ability to create high-quality, professional-looking labels.

How Do I Choose The Right Label Printer?

Consider factors such as the type of labels you need to print, the volume of labels you will be printing, and the features you require, such as connectivity options and label design software.

Conclusion

In conclusion, label printers are versatile devices that play a crucial role in creating high-quality labels for a wide range of applications. Understanding the different types of label printers and their key components, as well as how they work, is essential for making informed decisions when selecting a label printer for specific printing requirements. With their advanced printing technologies and numerous advantages, label printers continue to be indispensable tools for businesses and organizations worldwide.