Drilling through hard steel requires the right tools. A professional drill bit is essential.

Working with hard steel is tough. Standard bits won’t cut it. You need a specialized drill bit designed for the job. These bits are made from high-quality materials. They are built to withstand the rigors of drilling through hard steel.

Professionals rely on these bits for precise and efficient work. They save time and reduce wear and tear on equipment. In this post, we’ll explore the features of professional drill bits for hard steel. We’ll also discuss why they are a must-have for anyone working with this challenging material. Stay tuned to learn more about these essential tools.

Choosing The Right Drill Bit

Selecting the right drill bit for hard steel is essential. It ensures efficient and precise drilling. This guide helps you understand the types of drill bits and their material compatibility.

Types Of Drill Bits

Different drill bits serve different purposes. Here are some common types:

- Twist Drill Bits: These are versatile and common. Suitable for various materials.

- Cobalt Drill Bits: Ideal for hard steel. They withstand high temperatures.

- Carbide-Tipped Drill Bits: Perfect for drilling through tough materials. They are durable.

- Step Drill Bits: Good for drilling holes of various sizes. They offer precision.

Material Compatibility

Understanding material compatibility ensures better results. Here’s a quick guide:

| Material | Recommended Drill Bit |

|---|---|

| Hard Steel | Cobalt or Carbide-Tipped |

| Soft Metals | Twist or Step |

| Wood | Twist or Spade |

| Plastic | Twist or Step |

Using the correct drill bit for the material saves time and effort. Always check the material and choose the right drill bit accordingly.

Features Of High-quality Drill Bits

When drilling into hard steel, using the right drill bit is crucial. High-quality drill bits have specific features that make them effective and durable. These features ensure a smooth and efficient drilling experience.

Durability And Strength

High-quality drill bits are built to last. They are made from strong materials like cobalt or carbide. These materials resist wear and tear. They also prevent the drill bit from breaking easily. This means fewer replacements and lower costs in the long run. Strong drill bits can handle tough materials without bending or snapping.

Heat Resistance

Heat can damage drill bits. High-quality drill bits have excellent heat resistance. This feature keeps the drill bit cool during use. It also prevents overheating, which can cause damage. Heat-resistant drill bits perform better and last longer. They maintain their sharpness and effectiveness even under high temperatures.

Top Drill Bit Brands

Finding the right professional drill bit for hard steel can be challenging. With so many brands available, it’s essential to know which ones stand out. Here, we will discuss some of the top drill bit brands that are known for quality and durability.

Leading Manufacturers

Several manufacturers are well-known for producing high-quality drill bits for hard steel. Here are a few leading names:

- DeWalt: Known for durable and high-performance drill bits.

- Makita: Offers a wide range of reliable and efficient drill bits.

- Bosch: A trusted brand with excellent customer feedback.

- Irwin: Famous for their long-lasting and precise drill bits.

Drilling Techniques For Hard Steel

Drilling through hard steel can be challenging. Proper techniques make the job easier. Using the right drill bit is essential. But, your technique matters just as much. Let’s explore some important tips.

Drilling Speed And Pressure

Always start with a slow drilling speed. Hard steel requires patience. High speeds can overheat the bit. This weakens the drill bit quickly. Applying steady pressure is also crucial. Too much pressure can break the bit. Too little pressure won’t cut effectively. Find a balance for the best results.

Lubrication Tips

Lubrication helps reduce friction. It keeps the drill bit cool. Use a suitable lubricant for hard steel. Apply it to the bit before drilling. Reapply as needed during the process. This extends the life of your drill bit. It also ensures cleaner holes.

Safety Measures

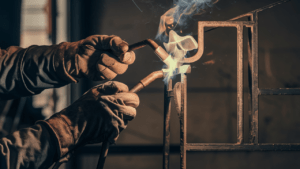

Using a professional drill bit for hard steel requires adherence to strict safety measures. Ignoring these can lead to injuries or damage. Below, we’ll discuss essential safety measures, focusing on protective gear and proper handling.

Protective Gear

Wearing the right protective gear is vital. This ensures your safety while working with hard steel. Below are the key items you need:

- Safety Glasses: These protect your eyes from flying debris.

- Gloves: Use cut-resistant gloves to protect your hands.

- Ear Protection: Drilling hard steel can be noisy. Use earplugs or earmuffs.

- Face Shield: For extra protection, use a face shield.

- Dust Mask: Protect your lungs from metal dust with a dust mask.

Proper Handling

Proper handling of the drill and drill bit is crucial. This not only ensures safety but also improves efficiency. Here are some important tips:

- Secure the Workpiece: Always clamp the steel securely before drilling. This prevents movement and ensures accuracy.

- Check Drill Speed: Use the correct drill speed for hard steel. High speeds can cause overheating.

- Apply Consistent Pressure: Apply steady, moderate pressure. Avoid forcing the drill bit.

- Lubricate the Drill Bit: Use cutting oil to reduce friction and prevent overheating.

- Inspect the Drill Bit: Regularly inspect the drill bit for wear and tear. Replace if necessary.

Following these safety measures ensures a safer and more efficient drilling process. Always prioritize your safety and the integrity of your tools.

Maintenance And Care

Proper maintenance and care of your professional drill bit for hard steel can extend its lifespan and ensure optimal performance. Regular cleaning, proper storage, and routine sharpening are essential to keep your drill bits in top condition.

Cleaning And Storage

After each use, clean the drill bits thoroughly. Remove any metal shavings and debris. Use a soft brush or cloth for best results. Dry the bits completely to prevent rust. Store your drill bits in a dry, cool place. Use a dedicated case or holder to avoid damage. Organize them by size for easy access and efficiency.

Sharpening Tips

Regularly check your drill bits for dullness. Use a bench grinder or sharpening tool to restore the edge. Follow the manufacturer’s instructions for the correct angle. Sharpen both sides evenly for balanced performance. Always wear safety goggles while sharpening. Test the drill bit on a scrap piece of steel. Ensure it cuts smoothly without excessive pressure.

Common Challenges

Drilling through hard steel can be a real challenge. Many professionals face common issues that can slow down their work. Understanding these challenges can help you choose the right drill bits and techniques to overcome them.

Bit Breakage

Bit breakage is a frequent problem when drilling hard steel. It usually happens when the bit is not strong enough for the material. Using the wrong drill speed or too much pressure can also lead to breakage. High-quality drill bits made from cobalt or carbide are less likely to break. Always check your drill speed and pressure to prevent breakage.

Heat Buildup

Heat buildup is another common challenge. Drilling through hard steel generates a lot of heat. Excessive heat can damage the drill bit and the material. It can also make the drilling process slower and less efficient. Using cutting fluid or coolant can help manage heat buildup. Taking frequent breaks also helps to cool down the drill bit.

Cost Vs. Quality

Choosing the right drill bit for hard steel can be tricky. Balancing cost and quality is key. Spending wisely ensures better performance and durability.

Budget-friendly Options

Budget-friendly drill bits are available. These bits are cheaper but may wear out quickly. They are a good choice for occasional use. Look for bits made from high-speed steel. They offer decent performance at a lower cost.

Investing In Premium Tools

Premium drill bits cost more but last longer. They are made from stronger materials like cobalt or carbide. These bits provide better precision and durability. For frequent use, investing in premium tools saves money over time. Quality bits reduce the need for frequent replacements.

Frequently Asked Questions

What Is The Best Drill Bit For Hard Steel?

The best drill bit for hard steel is usually made of cobalt or carbide. These materials are extremely durable and designed to withstand high temperatures, making them ideal for drilling through tough metals.

How Do You Drill Through Hard Steel?

To drill through hard steel, use a cobalt or carbide drill bit. Start with a slow speed and apply steady pressure. Lubricate the drill bit with cutting oil to reduce heat and friction.

Why Use Cobalt Drill Bits For Hard Steel?

Cobalt drill bits are ideal for hard steel because they are heat-resistant and durable. They retain their hardness at high temperatures, which helps in cutting through tough materials efficiently.

Can Regular Drill Bits Work On Hard Steel?

Regular drill bits are not recommended for hard steel. They can quickly become dull or break. For best results, use cobalt or carbide drill bits specifically designed for hard metals.

Conclusion

Choosing the right drill bit for hard steel is crucial. It ensures efficiency and precision in your work. Always consider the material, coating, and size of the drill bit. These factors impact performance and longevity. Investing in quality drill bits saves time and money.

Your projects will be smoother and more professional. Happy drilling!