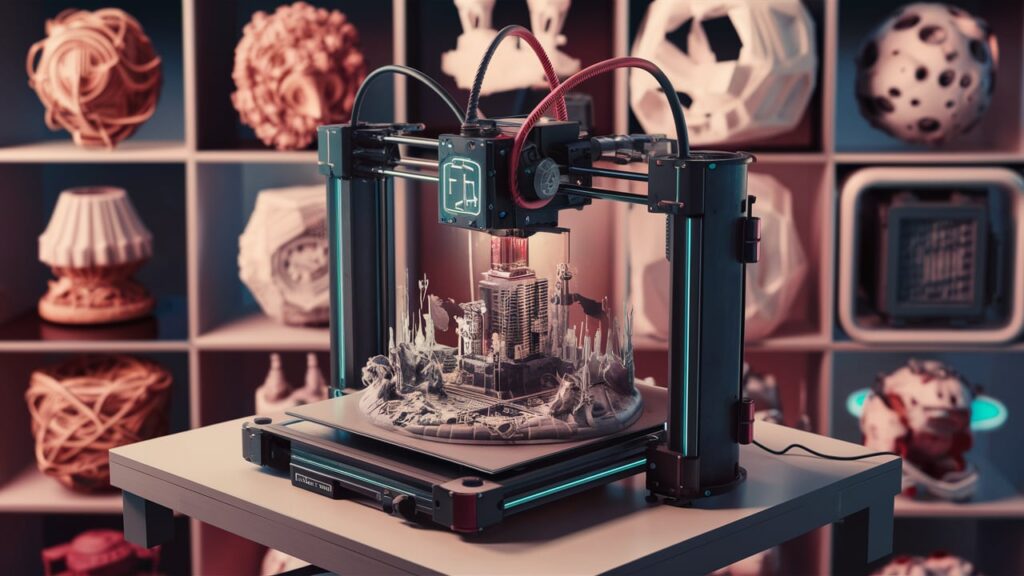

3D printing is transforming manufacturing. This innovative technology is changing how products are made.

Recommended Best Home Business Machines 2025-2026

| Business Ideas | Machines Link |

| Embroidered Apparel Business | Brother SE700 Sewing and Embroidery Machine |

| Flavored Nut Business | DYVEE Peanut Roaster For Home Use |

| Custom Sticker Business | Liene PixCut S1 Color Sticker Printer & Cutting Machine |

| Homemade Soap Business | PIUH Deluxe Soap Making Kit |

| Laser Craft Business | xTool F1 2-in-1 Dual Laser Engraver |

Manufacturing has seen many advances over the years, but 3D printing stands out. It offers new ways to design and produce items, making processes faster and more efficient. With 3D printing, companies can create complex parts with less waste and lower costs.

This technology is not just a trend; it is becoming a key part of modern manufacturing. From prototypes to final products, 3D printing is leading the way. It allows manufacturers to experiment and innovate like never before. This blog will explore how 3D printing is shaping the future of manufacturing. Stay with us to learn more about its impact and what the future holds.

Brief History

3D printing, also known as additive manufacturing, started in the 1980s. Dr. Hideo Kodama first developed a method for creating 3D models. Charles Hull later invented the first 3D printer in 1984. He called it stereolithography, or SLA. This printer used UV light to harden liquid resin into solid layers.

In the 1990s, new 3D printing methods appeared. Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM) became popular. These methods used different materials like plastic and metal. By the 2000s, 3D printing was being used in various industries. Today, it is a key tool in manufacturing.

Basic Principles

3D printing works by adding material layer by layer. It starts with a digital 3D model. This model is created using computer-aided design (CAD) software. The software slices the model into thin layers.

The printer reads these layers and builds the object. It adds one layer at a time. This process is repeated until the object is complete. Different materials can be used, like plastic, metal, and even food.

Here are some key terms in 3D printing:

- Extruder: The part of the printer that pushes out the material.

- Build Plate: The surface on which the object is built.

- Filament: The material used in FDM printers, usually plastic.

- Resin: The liquid material used in SLA printers.

Technological Advancements

The world of manufacturing is changing. 3D printing is at the forefront of this change. Technological advancements in 3D printing are making production faster, more precise, and more versatile. These improvements are reshaping how things are made. They are opening up new possibilities for the manufacturing industry.

Materials Innovation

One of the major advancements is in materials innovation. Early 3D printers used simple plastics. Now, a wide range of materials are available. These include metals, ceramics, and even bio-materials. This variety allows for more complex and durable products. Manufacturers can now create parts that are stronger and more heat-resistant.

| Material | Properties | Applications |

|---|---|---|

| Plastics | Lightweight, Flexible | Prototypes, Consumer Goods |

| Metals | Strong, Durable | Automotive, Aerospace |

| Ceramics | Heat-resistant, Hard | Medical Implants, Electronics |

| Bio-materials | Biocompatible, Renewable | Medical, Environmental |

Precision And Speed

Another key advancement is in precision and speed. New 3D printers are more accurate than ever. They can create complex shapes with tight tolerances. This precision reduces waste and improves product quality. Faster printing speeds also mean quicker turnaround times. This is crucial for industries that need to get products to market quickly.

Let’s look at some key benefits:

- Reduced lead times

- Lower production costs

- Increased flexibility in design

The combination of precision and speed is transforming manufacturing. It allows companies to be more agile and responsive. This helps them stay competitive in a fast-changing market.

Impact On Traditional Manufacturing

The advent of 3D printing is having a profound impact on traditional manufacturing. This technology is transforming how goods are produced. It offers numerous benefits that traditional methods cannot match. Let’s explore some key areas where 3D printing is making a difference.

Cost Reduction

One of the main advantages of 3D printing is cost reduction. Traditional manufacturing methods often require expensive molds and tools. These can be costly to produce and maintain. In contrast, 3D printing doesn’t need these tools. This reduces costs significantly. Companies save money on materials and labor.

In traditional manufacturing, creating complex shapes is expensive. 3D printing allows for intricate designs without additional cost. This means companies can create more complex products at a lower price.

Customization And Flexibility

3D printing offers unparalleled customization and flexibility. Traditional manufacturing methods produce items in large batches. This limits the ability to customize products for individual needs. 3D printing, on the other hand, allows for custom designs. Each item can be tailored to specific requirements.

For example, in the medical field, 3D printing can create custom prosthetics. These are tailored to fit the unique anatomy of each patient. This level of customization was not possible with traditional methods.

Additionally, 3D printing allows for rapid prototyping. Designers can quickly create and test new ideas. This speeds up the development process and allows for more innovation.

Applications In Various Industries

3D printing is transforming various industries. From healthcare to aerospace, its impact is vast. This section explores how different sectors benefit from this technology.

Healthcare And Medicine

3D printing has brought many advances to healthcare. It helps create custom prosthetics and implants. These devices fit better and are more comfortable for patients.

Medical researchers use 3D printing to produce organs and tissues. This helps in studying diseases and testing new drugs. It speeds up the research process and improves accuracy.

Surgeons use 3D-printed models for practice. They can plan surgeries more precisely. This reduces risks and improves patient outcomes.

Automotive And Aerospace

The automotive industry has embraced 3D printing. It allows for the creation of complex parts quickly. This reduces production time and costs.

Car manufacturers use 3D printing for prototyping. They can test new designs faster. This leads to more innovative and safer vehicles.

The aerospace industry also benefits from 3D printing. It produces lightweight yet strong parts for aircraft. This improves fuel efficiency and reduces emissions.

NASA and other space agencies use 3D printing for space missions. They can create tools and parts on demand. This is crucial for long-term missions in space.

Sustainability And Environmental Benefits

The world is becoming more aware of environmental issues. 3D printing is emerging as a solution for sustainable manufacturing. This technology offers significant environmental benefits. It reduces waste, saves energy, and promotes sustainable practices.

Waste Reduction

Traditional manufacturing often generates a lot of waste. Excess materials are discarded during production. 3D printing minimizes waste by using only the required materials. This process is known as additive manufacturing. Layers of material are added to create the final product. There is little to no excess waste. This method is more efficient and eco-friendly.

Energy Efficiency

3D printing can also lower energy consumption. Traditional methods require multiple steps and tools. Each step consumes energy. 3D printing streamlines the process. It reduces the need for multiple machines and tools. This leads to significant energy savings. The process is faster and more direct. Less energy is used, making it a greener choice.

Challenges And Limitations

3D printing has brought many changes to manufacturing. Yet, it faces many challenges and limitations. Understanding these can help us see its future better.

Material Constraints

Most 3D printers use plastic. This limits the strength and durability of products. Metals and ceramics are options, but they are costly. Not all printers can use these materials. This restricts the variety of products we can create.

Regulatory Hurdles

Regulations are a big challenge. Many countries have strict rules for 3D printed items. They must meet safety and quality standards. This process is often slow and costly. It can delay production.

Another issue is intellectual property. 3D printing can easily copy designs. This raises concerns over theft and protection of original work.

Future Trends

3D printing is transforming how industries manufacture products. The technology is evolving rapidly. This section explores future trends in 3D printing. These trends promise to reshape manufacturing on a global scale.

Integration With Ai

Artificial Intelligence (AI) is enhancing 3D printing. AI algorithms analyze data to improve print quality. They also predict potential issues before they occur. This reduces waste and increases efficiency. AI can also optimize designs for better performance. The combination of AI and 3D printing leads to smarter manufacturing processes.

Mass Adoption

The adoption of 3D printing is growing. More businesses are using 3D printers. The cost of 3D printers is decreasing. This makes the technology accessible to small companies. Large manufacturers are also investing in 3D printing. They use it to produce parts quickly and reduce inventory costs. Mass adoption will drive innovation and lower production costs.

Frequently Asked Questions

What Is 3d Printing In Manufacturing?

3D printing in manufacturing is a process of creating three-dimensional objects from digital files. It involves layering materials to form the final product.

How Does 3d Printing Benefit Manufacturers?

3D printing benefits manufacturers by reducing production time and costs. It allows for rapid prototyping and customization of products.

Can 3d Printing Improve Product Quality?

Yes, 3D printing can improve product quality by providing high precision and consistency. It allows for intricate designs that traditional methods may not achieve.

What Industries Use 3d Printing In Manufacturing?

Industries using 3D printing include automotive, aerospace, healthcare, and consumer goods. It’s popular for creating prototypes, tools, and end-use products.

Conclusion

3D printing is transforming manufacturing. It offers customization and efficiency. Costs reduce, and production speeds increase. Small businesses benefit from on-demand manufacturing. Industries innovate with new designs and materials. The future of manufacturing is bright with 3D printing. Embrace this technology and stay ahead.

Keep exploring its potential. Manufacturing will continue to evolve. 3D printing leads the way.