When it comes to working with tools, choosing the right type of sockets can make a significant difference in your projects’ outcomes. In this comprehensive guide, we will explore the key disparities between impact sockets and regular sockets.

Recommended Best Impact Sockets 2024-2025

| Recommendation | Product |

| Best Overall | NEIKO 02448A 1/2″ Drive Master Impact Socket Set |

| Popular Choice | SUNEX TOOLS Drive Master Impact Socket Set |

| Best Value | WORKPRO 1/2″ Drive Impact Socket Set |

| Best Budget | AOBEN Drive Impact Socket Set |

| Another Excellent Pick | AMM 66 Pieces Impact Socket Master Set |

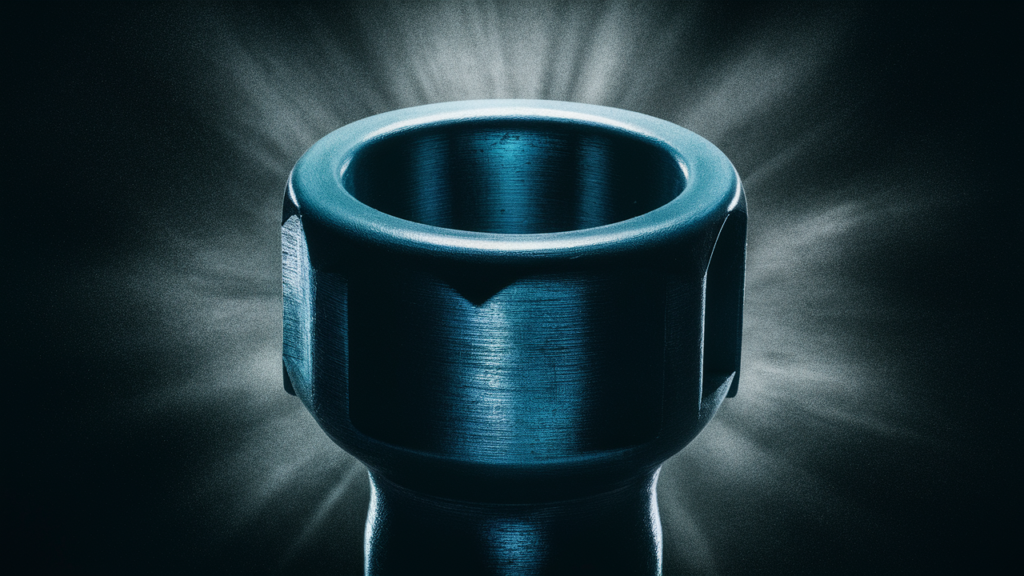

1. Impact Sockets

Impact sockets are specifically engineered to withstand high levels of torque produced by impact wrenches or air tools. They are crafted from robust materials such as chrome molybdenum, known for its durability and ability to handle intense pressure.

- Designed for use with impact wrenches

- Made from chrome molybdenum for enhanced strength

2. Regular Sockets

On the other hand, regular sockets, commonly made of chrome vanadium, are suitable for standard hand tool applications but may not endure the force generated by impact tools. They are better suited for lighter tasks that do not require high impact resistance.

- Ideal for conventional hand tool usage

- Mainly constructed from chrome vanadium

Key Differences

| Aspect | Impact Sockets | Regular Sockets |

|---|---|---|

| Material | Chrome molybdenum | Chrome vanadium |

| Usage | Heavy-duty applications | Light to medium-duty tasks |

| Strength | High impact resistance | Limited impact resistance |

Impact Vs Regular Sockets: When To Use Which?

If you are working with high-torque tools like impact wrenches or air tools, opting for impact sockets is crucial to prevent breakage and ensure safety. Regular sockets are more suited for tasks that involve standard hand tools where impact resistance is not a primary concern.

Why Choose Impact Sockets

Impact sockets offer superior strength and durability, making them ideal for heavy-duty applications that involve high levels of force. Using regular sockets with impact tools can lead to socket failure and potential safety hazards.

Conclusion

Choosing between impact sockets and regular sockets ultimately depends on the nature of your work. For tasks requiring high impact resistance, such as using impact wrenches, investing in impact sockets is the way to go. However, for lighter applications using standard hand tools, regular sockets may suffice.

Frequently Asked Questions

Do You Really Need Impact Sockets?

Absolutely! Impact sockets are crucial for using heavy-duty pneumatic tools like an impact wrench. Regular sockets can shatter under the pressure, causing injury. Choose impact sockets for safety and durability.

What Happens If You Use Non-impact Sockets?

Using non-impact sockets with an impact tool can result in shattering or damage to the socket.

Can You Use Impact Sockets On A Regular Drill?

Yes, you can use impact sockets on a regular drill for general purposes without any issues.

Why Are Impact Sockets Different Than Chrome Sockets?

Impact sockets are designed to withstand the high torque of impact tools. They are made of tougher steel and have thicker walls compared to chrome sockets. This prevents breakage and ensures safety when using impact wrenches.